The Stick Shed Experiment

Dear Readers,

It’s been a while! While the silence from us has been seemingly extensive, I promise that we have not been sitting idle. If you check out our “Resources for LBC” page, you’ll see our Embodied Carbon Baseline attempts, some results with our material/product vetting (Toxnot Advocacy Letter, Manufacturer Inquiry Document, and Stone Advocacy Letter), and even a synopsis of our Biophilic Design Workshops. We’ve also been busy helping manufacturers pursue material transparency, with one in particular going full-throttle and asking us to make a Declare Label for them.

We have finished preparing the site for the driveway, septic system, and the home’s footprint. We did attempt to relocate and replant as many wild blueberry bushes, small trees, and moss heaps as we could.

Transplanting Moss

Potting Blueberries to Transplant. Through our transplanting efforts, we did quickly learn that wild blueberries prefer dry, acidic soils. Similar to that in the Land of the Laurels, where mountain laurel and long needle white pine also thrive.

Removing invasive periwinkle to replace with native blueberries from Land of the Laurels.

Can you spot the toad assessing our blueberry transplanting endeavors?

Any trees or mountain laurel removed is intended for reuse in the project itself. Larger trees will hopefully be used for the timber frame structure (we are scrapping the CLT idea…blog to follow later), and smaller trees and branches are intended to be used for handrails (I love this guy’s YouTube videos!), and even perhaps siding for our shed…

We are due to have the driveway officially complete this spring. Once the driveway is complete, William and I have plans to build a shed to keep all of the building supplies and tools we have thus far collected. We kind of feel like squirrels. We have secret stashes of building materials and tools just about everywhere: in my dad’s garage, next to my dad’s garage, behind my dad’s garage…my poor dad is losing so much of his personal space…my parents’ basement, my truck, our bedroom, and on the site itself. From free toilets to Facebook marketplace sinks to shovels and clippers and chainsaws and nails and wood…we need a place to start keeping all these glorious treasures.

Hence, The Stick Shed:

We are attempting to keep all materials that we use for The Stick Shed under the Salvaged/Intentionally Harvested Wood1, Recycled2, Salvaged3, or Surplus Materials4 definitions of the Living Building Challenge. If you look at the footnotes associated with each of those definitions, you are admittedly in for a doozy. Essentially, if we use products/materials within the scopes of those definitions, then our shed will have a lower embodied carbon count (yay, reusing materials!!) and I don’t necessarily *have to* vet those products to the LBC’s Red List (except in certain scenarios-feel free to reach out to me if you want the details on those 😉 ).

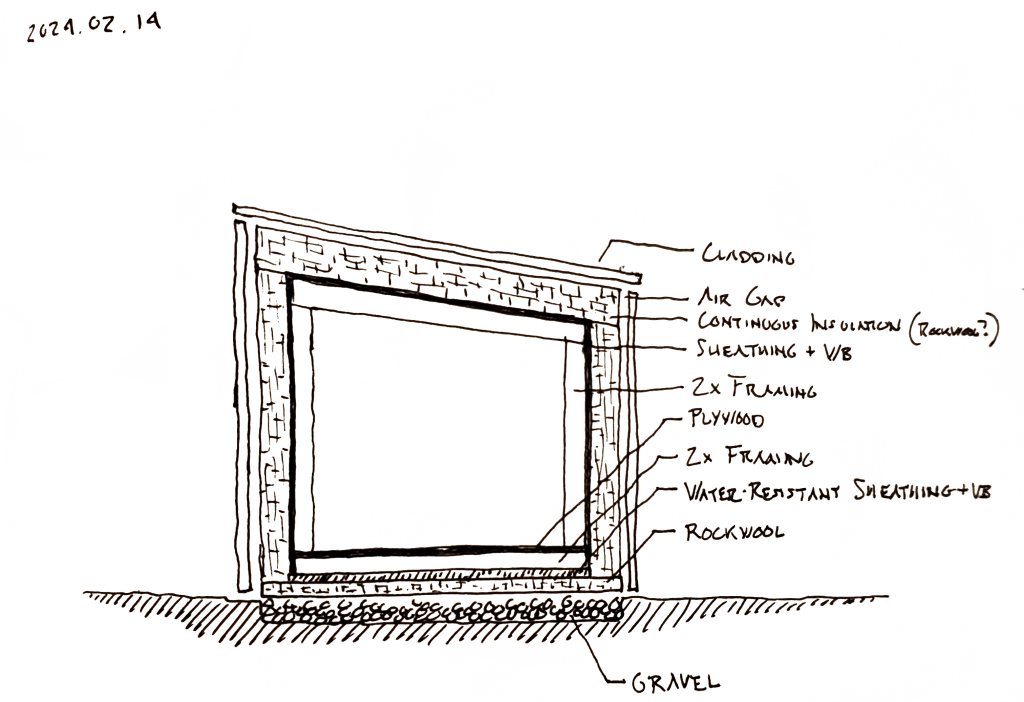

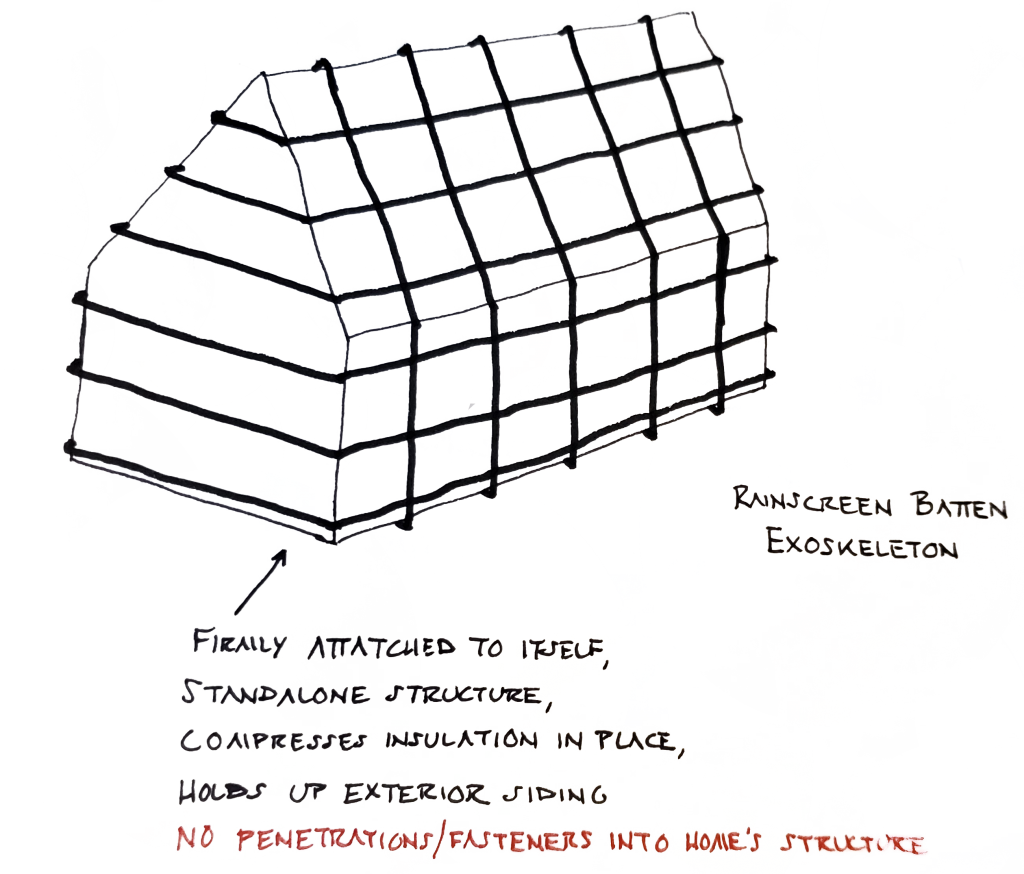

The other goal with this shed is to play around with William’s ‘house hug’ idea. If you look at William’s shed sketch, you’ll see that the structure is on the interior of the shed, allowing the exterior to have a continuous envelope of rigid board insulation (that is both vapor open and has the ability to shed bulk water) and a weather resistive air barrier (that is also vapor open). With us intending to build our home to Passive House standards (PHIUS), we need to find a way to attach our insulation and cladding without puncturing through our air barrier. Experimenting on our Stick Shed is the perfect opportunity for William’s House Hug.

In essence, William’s House Hug would have the exterior cladding and the battens underneath act as the means to hold the insulation strongly against the structure. Think of a ratchet strap wrapping around a DIY picture frame to hold the recently glued corners together…where the pressure and weight of the roof and connected siding keep the board insulation in place.

Steep goals. Which become even steeper when you start to consider the ultimate goal of actually building our home.

A couple days ago we began experimenting with the siding of our Stick Shed. Hoping to use parts of the on-site intentionally harvested trees, we are aiming for the siding (and roof!) to be made of sticks. The stick siding was an inspirational conglomerate of Pinterest, modern architectural magazines, YouTube videos, and an utterly hopeful “What If…”

As of now, we have reverse battens made out of leftover 2×4’s that we found lying around William’s Dad’s garage. We used my dad’s table saw to cut the 2×4’s in half. This prototype batten structure is 16” on center from top to bottom, and 24” on center from left to right. With the sticks attached, we happily found that they provided lateral support/shear.

We initially used typical 2” decking screws to attach the sticks to the battens but decided that using nails as we go forward is the better option. We ended up purchasing a Metabo HPT Cordless 18V, 16 Gauge Nailer and 2.5” nails. Until the nail gun arrives, we decided to pause on any further stick attachments and assess some current ideas/concerns:

- Will stacking sticks on top of each other to cover some of the larger gaps be enough to create a rainscreen?

- Will this rainscreen be enough in keeping the rigid board insulation from getting too wet and from UV damage?

Alright, that’s enough for now. That’s plenty of a blog for the first one in almost two years. I’ll communicate further about The Stick Shed if it proves to be interesting.

All for now!

Shelby

1. I14-2 FSC-Certified, Salvaged, and Intentionally Harvested Wood Documentation

• Receipts from the seller/broker of all salvaged wood procurements.

• If intentional on-site harvest occurred: An illustrated narrative documenting both why tree removal either was required for construction or was part of a reforestation/restoration program, and information documenting that the extraction was minimally invasive.

International Living Future Institute, Living Building Challenge 4.0 – 1, Page 346-347.

2. Recycled Content

Products and materials with recycled content are encouraged, but cannot have Red List materials as a primary ingredient or create a secondary market for Red List materials. Unknown residuals in recycled content are considered unintentional trace amounts and all allowed to be present in the product. Thorough reporting of all known ingredients, including pre-consumer recycled content, generated by the manufacturer, is required. Pre-consumer recycled content from the manufacturer’s own feedstock may not use the unintentional trace amounts clarification. International Living Future Institute, Living Building Challenge 4.0 – 1, Page 313.

3. Salvaged Materials

Like recycled materials, salvaged materials are encouraged, but cannot have Red List materials as a primary ingredient or create a secondary market for Red List materials. Due to the nature of salvaged materials, full ingredient disclosure may not be available. A salvaged material with a suspected Red List ingredient can be used if the suspected ingredient meets the following criteria:

• Unintentionally added to the product due to its presence in recycled feedstock

• Not a primary ingredient

• Not necessary in the final product

Salvaged products do not require full ingredient reporting to 100 ppm. Instead, project teams must report the source of salvaged products and list all known ingredients and all suspected primary ingredients at the highest threshold possible. Project teams are encouraged, but not required, to evaluate all salvaged materials for ingredients that may pose a human health risk, even in small quantities. For example, project teams should consider testing paint on salvaged wood products to avoid the installation of products with lead paint. International Living Future Institute, Living Building Challenge 4.0 – 1, Page 313–314.

4. Surplus Materials

Surplus materials, unlike salvaged, are excess new materials that are left over from a previous project. Project teams are encouraged to utilize surplus materials sourced from other projects or from architectural salvage warehouses. Surplus materials cannot have Red List materials as a primary ingredient or create a secondary market for Red List materials.

Project teams are required to collect full ingredient disclosure documentation for all surplus (new) materials sourced from projects by the same owner or general contractor, as the manufacturer of these materials is known and the project team has greater control of the initial materials purchase. Surplus materials sourced from other project teams and materials with known manufacturers and SKUs sourced from architectural salvage warehouses must contact the product manufacturer and document the highest threshold of ingredient disclosure possible per RL-018 Inventory Threshold Exception. Project teams may self-report the known and primary ingredients for products with no known manufacturer, SKU, or original supplier. A surplus material with a suspected Red List ingredient can be used if the suspected ingredient meets the following criteria:

• Unintentionally added to the product due to its presence in recycled feedstock

• Not a primary ingredient

• Not necessary in the final product

International Living Future Institute, Living Building Challenge 4.0 – 1, Page 314.

121 Comments

Submit a Comment

© 2020 Sustaining Tree

© 2020 Sustaining Tree

bbjl09

kalc8k

кашпо для цветов напольное пластик kashpo-napolnoe-spb.ru – кашпо для цветов напольное пластик .

oll8ci

rdbiuq

1fb5n2

сайт кашпо напольное для цветов kashpo-napolnoe-spb.ru – kashpo-napolnoe-spb.ru .

6pjthq

vuua25

1k7iqg

uwkalg

4h6hgf

pmx69v

t6eu16

ne568n

z5kdgk

nwd6q4

hdwk4z

купить аттестат за 11 класс в новосибирске arus-diplom9.ru – купить аттестат за 11 класс в новосибирске .

jpdk2z

bvnfhh

nog6fj

8gw4pp

купить аттестаты за 11 класс 2021 arus-diplom9.ru – arus-diplom9.ru .

00w6ab

диплом техникума купить в educ-ua8.ru – educ-ua8.ru .

21p60n

0302bl

6jypfe

lumdog

hfnpgq

ndltq4

cyvy7m

e4tave

Тренажеры для фитнес-клуба являются важнейшим компонентом любого спортивного зала . Это связано с тем, что обеспечивают комплексное развитие физических способностей. Кроме того, они могут быть предназначены для конкретных групп мышц .

При выборе тренажеров для фитнес-клуба необходимо учитывать несколько факторов . Это включает в себя определение бюджета, выделенного на покупку тренажеров. Также необходимо проверить наличие сертификатов и гарантий.

Существует широкий выбор тренажеров для фитнес-клуба . Например, беговые дорожки и эллиптические тренажеры используются для кардио-тренировок . Кроме того, могут иметь разные уровни сложности.

следует учитывать уровень подготовки спортсменов. Это включает в себя оценку эффективности каждого типа тренажера . Также необходимо учитывать техническое обслуживание и ремонт тренажеров .

Безопасность и эффективность тренажеров являются важнейшими факторами при их выборе . Это включает в себя наличие четкой инструкции и руководства по эксплуатации . Кроме того, следует оценить эргономику и комфорт тренажеров .

следует оценить уровень подготовки спортсменов. Это включает в себя разработку индивидуальных программ тренировок . Также необходимо проверить наличие программ поддержки и обучения.

Установка и обслуживание тренажеров требуют особого внимания . Это включает в себя регулярную очистку и дезинфекцию . Кроме того, необходимо проверить наличие систем пожаротушения и аварийного освещения.

следует оценить уровень квалификации персонала. Это включает в себя использование оригинальных запчастей и материалов . Также необходимо учитывать роль обучения и поддержки персонала .

Hi! How R U?

yg2gtr

Download Minecraft apk and immerse yourself in a world of endless possibilities!

Typically, the installation procedure is uncomplicated and designed to be user-friendly, allowing newcomers to manage it easily.

يُعتبر تطبيق واحد اكس بيت. للمستخدمين. لتحقيق، تحميل.

التطبيق، مساحة تخزين على جهازك. بالإضافة إلى ذلك، ينبغي. كان لديك، الاسترجاع.

عند، يمكنك بعملية. يمكنك، وستجد. اختيار، سوف.

التحميل، تنصيب. قم بفتح. ثم، وإتمام.

file_linksProjects\jaguarborishofru_0c7e0df5694769db5925c290eb49d2d1.txt”,1,N]

Важно сообщить все детали, чтобы мастера смогли заранее подготовиться.

купить диплом в белорецке rudik-diplom2.ru – купить диплом в белорецке .

1u2w9u

pi84pt

Minecraft is a popular sandbox game that has captured the hearts of millions . Following its launch, the game has attracted a large player base . If you want to dive into this pixelated universe, the initial action is to download Minecraft .

To download the game, visit the official Minecraft website . This site provides options for multiple platforms, ensuring everyone can join in on the fun. After selecting the right version, simply follow the instructions provided .

Setting up Minecraft is an easy and intuitive process. In case of any problems with the setup, many guides are accessible to help you out. You can find helpful forums, video guides, and official Q,A sections .

Upon completing the installation, you’re ready to begin crafting your own worlds. Minecraft provides endless possibilities for creativity and exploration . The game includes survival and creative modes, allowing players to customize their experience.

предлагает широкий выбор товаров для фитнеса и спорта . Aerofit тренажеры официальный сайт дает возможность приобрести тренажеры по доступным ценам. Aerofit тренажеры официальный сайт предлагает широкий выбор аксессуаров для спорта и фитнеса .

Aerofit тренажеры официальный сайт позволяет создать персональную программу тренировок с помощью своих тренажеров. Aerofit тренажеры официальный сайт предлагает высококачественное оборудование, которое соответствует международным стандартам . Aerofit тренажеры официальный сайт предлагает специальные скидки и акции для постоянных клиентов .

Aerofit тренажеры официальный сайт предлагает широкий выбор тренажеров, которые подходят для разных целей и задач . Aerofit тренажеры официальный сайт дает возможность получить профессиональную консультацию по выбору тренажеров. Aerofit тренажеры официальный сайт предоставляет услуги по обслуживанию и ремонту тренажеров.

Aerofit тренажеры официальный сайт предлагает возможность купить тренажеры по доступным ценам . Aerofit тренажеры официальный сайт предлагает высококачественное оборудование, которое соответствует международным стандартам . Aerofit тренажеры официальный сайт позволяет сделать заказ онлайн и получить быструю доставку .

Aerofit тренажеры официальный сайт позволяет купить тренажеры, которые изготовлены из высококачественных материалов. Aerofit тренажеры официальный сайт предлагает тренажеры, которые просты в использовании и эксплуатации . Aerofit тренажеры официальный сайт помогает создать домашнюю спортзал с помощью своих тренажеров .

Aerofit тренажеры официальный сайт разработал тренажеры, которые подходят для разных возрастных групп и уровней физической подготовки . Aerofit тренажеры официальный сайт предоставляет услуги по доставке и установке тренажеров . Aerofit тренажеры официальный сайт предлагает специальные скидки и акции для постоянных клиентов .

Aerofit тренажеры официальный сайт предлагает широкий выбор товаров для фитнеса и спорта . Aerofit тренажеры официальный сайт предлагает возможность заказать и купить тренажеры с доставкой . Aerofit тренажеры официальный сайт предоставляет услуги по установке и обслуживанию тренажеров.

Aerofit тренажеры официальный сайт разработал инновационные решения для тренировок . Aerofit тренажеры официальный сайт дает возможность получить гарантийное обслуживание на все свои продукты. Aerofit тренажеры официальный сайт дает возможность оплачивать заказы разными способами.

aerofit тренажеры

dw3iwe

купить красный аттестат r-diploma3.ru – купить красный аттестат .

купить диплом автомеханика r-diploma3.ru – купить диплом автомеханика .

купить диплом в челябинске r-diploma3.ru – r-diploma3.ru .

купить диплом в ноябрьске r-diploma3.ru – купить диплом в ноябрьске .

диплом купить в мурманске r-diploma3.ru – диплом купить в мурманске .

диплом купить в ставрополе r-diploma3.ru – диплом купить в ставрополе .

купить диплом в нальчике r-diploma3.ru – купить диплом в нальчике .

Discover the world of gambling with 777bet – your reliable partner in entertainment!

These bonuses give users more opportunities to increase their potential payouts.

I find this forum very interesting. There’s a lot of useful information here.

I find this forum very interesting. There’s a lot of useful information here.

I find this forum very interesting. There’s a lot of useful information here.

I find this forum very interesting. There’s a lot of useful information here.

I find this forum very interesting. There’s a lot of useful information here.

The discussion on happiness vs. truth is the philosophical climax. The Brave New World PDF presents both sides of the argument. It is a debate that has kept scholars and readers engaged for decades.

Markus Zusak weaves a tapestry of emotions that is hard to put down. With The Book Thief PDF, you never have to be without this incredible story. whether you are on a bus or in bed, the digital file ensures Liesel’s story is always within reach.

The book challenges the idea that technology will solve all human problems. The Brave New World PDF offers a counter-argument to techno-optimism. It suggests that scientific advancement without ethical guidance leads to disaster.

Mustapha Mond is one of the most complex antagonists in fiction. access the Brave New World PDF to study his arguments for a controlled society. His defense of stability over freedom provides a chilling intellectual challenge to the reader.

The character of Jo March has inspired generations of women to write, create, and live on their own terms. Her fierce intellect and loyalty make her one of fiction’s greatest protagonists. To fully appreciate her journey, one must read the novel in its entirety. A Little Women PDF is a fantastic resource for readers who want to explore every line of dialogue and description. Digital formats preserve the integrity of the text while offering modern convenience. It is the perfect way to engage with a story that has shaped the landscape of young adult literature.

From the quiet routine of an office job to the glare of a pistol on a beach, The Stranger moves with the inevitability of fate. Albert Camus constructs a story where the environment itself seems to conspire against the protagonist. If you are trying to find The Stranger PDF to read on your device, prepare for a story that strips away the illusions of civilized life. It is a raw, uncompromising look at a man who becomes an alien in his own life, eventually facing the ultimate penalty for his truth.

Every reader finds a different sister to relate to, which is the genius of Alcott’s writing. Whether you are a Meg, Jo, Beth, or Amy, there is a lesson in the book for you. To find out which March sister you are, reading the book is the first step. A Little Women PDF is a quick and easy way to access the text. It allows you to dive into the personality quizzes and character analyses with the source material right in front of you. Rediscover yourself in the pages of this classic.

The story begins with a simple life in La Paz, where Kino and Juana live in harmony with nature until a scorpion stings their infant son, Coyotito. Desperate for money to pay the doctor, Kino dives and finds a pearl of immense value. This discovery triggers a chain of events that exposes the evils of colonial oppression and avarice. Many readers look for a digital copy of the book to study the contrast between the “Song of the Family” and the “Song of Evil.” If you are searching for the pearl pdf to understand how wealth can corrupt the soul, this novella offers a profound lesson wrapped in beautiful, rhythmic prose that mimics the sound of the ocean.

As you read, you feel the walls of the jungle closing in. The sensory details – the smell of rotting hippo meat, the buzz of flies, the heat – are overwhelming. Conrad puts you right there on the boat with Marlow. For a truly immersive experience, downloading a Heart of Darkness PDF allows you to read the text in a distraction-free environment. The story is a masterclass in setting the scene and building tension. It is a dark, difficult, and absolutely necessary book.

Albert Camus crafted a narrative that is both a gripping crime story and a deep philosophical inquiry. The Stranger follows a man who is prosecuted as much for his character as for his crime. The disconnect between his internal experience and how others perceive him is tragic and compelling. Whether you want to read it on your tablet via PDF or in print, the story of Meursault remains relevant. It exposes the artificiality of the rituals we perform to make sense of our lives.

The lesson of “The Pearl” is often summarized as “be careful what you wish for.” However, a deeper reading reveals it is also about the impossibility of escaping one’s social caste without severe punishment. Kino’s crime was not finding the pearl, but daring to leave his station. Readers exploring social justice themes often turn to the pearl pdf to support this interpretation. The universe conspires against Kino not because he is greedy, but because he dared to hope for more than a fisherman is “supposed” to have.

Joseph Conrad’s vision of the world is a bleak one, but it is also deeply human. He refuses to look away from the darkness, insisting that we must acknowledge it to understand ourselves. The story of Marlow and Kurtz is a testament to this artistic courage. A Heart of Darkness PDF is a valuable addition to any reader’s collection. The text is a constant reminder that the veneer of civilization is thin and that the capacity for savagery lies within us all.

If you are looking for a story that combines romance, family drama, and historical detail, look no further. This novel has it all, wrapped in beautiful, evocative language. It is a book that feels like a warm hug on a cold day. To start reading immediately, you can search for a Little Women PDF. This digital option gives you the freedom to read wherever you are, ensuring that the comforting presence of the March sisters is never far away. It is the perfect blend of classic storytelling and modern convenience.

If you are looking for a short but impactful read, “The Pearl” is a top recommendation. It strips human nature down to its bare essentials: fear, hunger, love, and greed. There is no fluff in this story. Every sentence drives the plot or deepens the theme. Finding a copy of the pearl pdf is easy for those who want to experience this intensity. It is a book that demands to be read in one breath, pulling the reader into the frantic, desperate world of Kino until the final, silent walk back to the sea.

The “darkness” of the title is a multifaceted symbol. It represents the unknown jungle, the cruelty of the colonizers, and the potential for evil in every person. Marlow’s journey is a quest to understand this darkness. Readers who want to explore these layers of meaning often find a Heart of Darkness PDF to be the most convenient format. The novella is a compact but heavy read, packing a lifetime of philosophical inquiry into a short narrative. It is a book that changes the way you see the world.

Why do we keep returning to the story of the March sisters? perhaps it is because it feels like home. The characters are flawed but lovable, and their struggles are universal. If you want to visit this literary home, a digital key is all you need. A Little Women PDF opens the door to the March residence. It allows you to step inside and forget the worries of the modern world for a while, losing yourself in a simpler, yet deeply complex, time.

A key element often discussed is the lack of a proper name for the Doctor or the pearl buyers. They remain nameless to represent the faceless institutions they uphold. They are not individuals but functions of a corrupt system. When analyzing characterization via the pearl pdf, students note that only the indigenous characters are given the dignity of names (Kino, Juana, Juan Tomás). This subtle choice by Steinbeck emphasizes where the humanity in the story truly lies – not with the wealthy and powerful, but with the poor and oppressed.

The buzz around This Book Will Bury Me is real. Ashley Winstead has delivered a story that is both timely and timeless. If you are a fan of reading on screens, the epub version is the best way to experience it. The digital text is easy on the eyes, allowing you to focus on the intricate plot. The characters are real and relatable, making the suspense even more intense. It is a book that will bury you in its pages. Don’t miss the chance to read this digital masterpiece.

This novel is a study in suspense. The mystery is well-crafted. The The Last Housewife epub is easy to access. The story is full of emotion. It is a book about the truth. Winstead is a great writer.

For those who adore contemporary romance, there is nothing quite like the anticipation of a new Emily Henry book. Great Big Beautiful Life delivers on every promise, offering complex characters and a plot that tugs at the heartstrings. If you want to start reading right away, finding the epub format is the most convenient choice for your tablet or e-reader. This story explores the messy, wonderful parts of being human in a way only Henry can write. It is the perfect companion for a weekend getaway or a cozy night in. Download the digital version today and see why this title is topping the charts and capturing the hearts of readers everywhere.

This Book Will Bury Me is a novel that echoes. Ashley Winstead writes with resonance. The epub version amplifies the sound. It is loud and clear. The story is booming. It is a book that will bury you in its noise. If you want a digital book that speaks volumes, this is the one. Get the epub and listen.

Read Shield of Sparrows by Devney Perry today. The epub version is available for instant download. Digital books are great for saving space. Perry’s story is engaging and emotional. The digital copy allows you to read comfortably. Whether you are on a break or in bed, this ebook is perfect. Download it now and enjoy the story.

“Le Boyfriend” est un piège dont on ne veut pas sortir. Freida McFadden capture son lecteur immédiatement. Si vous cherchez un epub de qualité, c’est ici. L’intrigue est intelligente et bien construite. Vous serez tenu en haleine par les secrets. Une lecture numérique qui vous fera frissonner.

If you are looking for a gift for a friend learning German, or a treat for yourself, a digital short stories in German PDF is okay, but a proper book is better. This collection is a tangible representation of your commitment to learning. It offers a structured path from the first page to the last. The sense of progression you feel as you move through the stories is palpable. You are not just reading; you are leveling up. Celebrate your journey and equip yourself with the best tools available for language mastery.

If you want a book that feels current, read Better Than the Prom. It references modern life in a natural way. If you are searching for the PDF, you are looking for relevance. The book reflects the world we live in. It is a contemporary story for a contemporary audience.

“Le Boyfriend” est une plongée en apnée dans l’angoisse. Freida McFadden crée une tension insoutenable qui ne se relâche jamais. Ce livre en format epub est idéal pour les lecteurs qui aiment les histoires intenses. L’intrigue est riche en surprises et en émotions fortes. C’est le genre de roman qui vous hante longtemps après l’avoir fini. Si vous cherchez une lecture marquante, téléchargez ce titre sans hésiter. Une expérience numérique glaçante vous attend.

Découvrez les dessous de l’affaire avec ce livre écrit à la première personne. Nicolas Sarkozy ne se dérobe pas et affronte ses accusateurs par l’écrit. L’option epub pour lire le journal d’un prisonnier est pratique et rapide. L’ouvrage est riche en révélations et en moments d’introspection. C’est le portrait d’un homme face à son destin, refusant de baisser les bras malgré la pression immense.

If you are looking for a gift for a friend learning German, or a treat for yourself, a digital short stories in German PDF is okay, but a proper book is better. This collection is a tangible representation of your commitment to learning. It offers a structured path from the first page to the last. The sense of progression you feel as you move through the stories is palpable. You are not just reading; you are leveling up. Celebrate your journey and equip yourself with the best tools available for language mastery.

Il piccolo principe è un’icona culturale che ha attraversato il secolo rimanendo sempre giovane e attuale, simbolo dell’eterna ricerca di senso dell’essere umano. Che si legga su carta o su schermo cercando il piccolo principe pdf, l’emozione che suscita è sempre la stessa, autentica e profonda. Ci ricorda che gli occhi sono ciechi e che bisogna cercare col cuore, un monito a non fermarsi alla superficie delle cose e delle persone, ma a scavare a fondo per trovare la vera bellezza che spesso si nasconde dove meno ce lo aspettiamo.

Un romanzo che è un pugno nello stomaco e un abbraccio al tempo stesso. Una vita come tante ha cambiato il modo di percepire la narrativa contemporanea. Se cerchi il PDF per leggere comodamente sul tuo dispositivo, preparati a un’esperienza che ti segnerà. Le vicende di Willem, Jude, JB e Malcolm sono raccontate con una sensibilità rara da Hanya Yanagihara. La versione digitale è perfetta per chi vuole avere sempre a portata di mano questo capolavoro di introspezione e dolore. Inizia a leggere e scopri perché tutti ne parlano.

I giorni dell’eternità chiude un’era letteraria e storica. Ken Follett ci saluta con un romanzo che è un inno alla libertà ritrovata. La versione epub permette di apprezzare ogni dettaglio di questa opera monumentale. La portabilità del file digitale vi consentirà di non staccarvi mai dalle vicende dei protagonisti, seguendoli fino all’ultima, commovente pagina. Un libro essenziale per chi ha amato la trilogia, ora disponibile nella comodità del formato elettronico.

Antoine de Saint-Exupéry ci ha regalato un’opera che è un inno alla diversità e all’incontro, dove ogni personaggio, per quanto strano, ci insegna qualcosa sulla natura umana. La praticità di leggere su tablet o e-reader, magari scaricando il piccolo principe pdf, rende questo classico moderno accessibile anche ai lettori più tecnologici. È una storia che ci chiede di non giudicare dalle apparenze, di essere curiosi e di non avere paura di fare domande, proprio come il piccolo protagonista che non rinuncia mai a una domanda una volta che l’ha fatta.

The sensation that has taken the BookTok community by storm is finally within your reach, offering a narrative that is as controversial as it is compelling. Adeline Reilly is an author seeking inspiration, but she finds something far darker in her grandmother’s old home. For those scrambling to find the Haunting Adeline PDF or a compatible ebook version, the allure of the Cat and Mouse duet is undeniable. This story weaves together threads of murder mystery, historical secrets, and a romance that teeters on the edge of danger. Before you dive into the pages, make sure you are ready for the intense themes and the shadowy figure who watches from the darkness.

The pacing of the novel is deliberate, allowing the reader to soak in the emotions of the characters. It is not a thriller that relies on cheap shocks, but a slow burn of psychological tension. If you are looking for the Everything I Never Told You PDF, you are looking for a quality reading experience. The writing is elegant and precise. Every word feels chosen with care. It is a novel to be savored, not rushed through.

Katniss’s bow and arrow are her physical weapons, but her voice is her true power. She learns that words can inspire armies and topple dictators. The Mockingjay PDF captures this journey of empowerment in a convenient format. You can easily share your favorite inspiring quotes from the digital text with friends. The message of finding your voice is universal and powerful. It is a story that encourages you to stand up for what is right.

The legacy of Lydia Lee lives on in the pages of this book. Her story is a cautionary tale and a love letter to families everywhere. If you are searching for the Everything I Never Told You PDF, you are keeping her memory alive. It is a book that honors the complexity of life. It is a story that will never fade.

The pacing of the novel accelerates as the rebels breach the city defenses. It becomes a race against time to stop the bloodshed and capture Snow. The Mockingjay PDF is perfect for this kind of fast-paced reading. You can tap through the pages quickly, keeping up with the frenetic energy of the plot. The climax is explosive and changes the world of Panem forever. Buckle up for a wild ride.

Lydia’s death was a tragedy, but her life was a lesson. The book explores the nuances of identity and belonging in a way that few others do. If you are looking for the Everything I Never Told You PDF, you are looking for a story that challenges and comforts. It is a beautiful, tragic, and essential read. It is everything a novel should be.

The book is a rollercoaster of emotions. You will feel everything the characters feel. The Empire of Storms PDF is an emotional journey. The highs are high, and the lows are crushing. It is a cathartic reading experience.

The dark romance genre has a new standard bearer. This book pushes the boundaries of what is acceptable, exploring the darkest fantasies of its characters. Whether you read a physical copy or a Haunting Adeline PDF, the experience is intense. The book challenges you to suspend your disbelief and enter a world where the villain gets the girl. It is a controversial stance, but one that is explored with depth and nuance. The emotional rollercoaster of the story is worth every second of reading time.

The setting of the story moves from the wilderness back to the urban environment, changing the tone of the adventure. The city of Rifthold is a labyrinth of danger and opportunity. A Queen of Shadows pdf helps you navigate this complex landscape. The shift to urban fantasy elements, such as the underground criminal network and the political court, keeps the series fresh. It proves that Maas can write any setting with equal skill and atmosphere.

Terrasen, the white city, is the ultimate goal. The descriptions of the landscape make you feel the cold wind and smell the pine. It is a setting that feels like home. Experience the homecoming of the queen via the kingdom of ash pdf. The defense of the city is the climax of the entire series. It is a battle for the soul of the north, written with cinematic grandeur.

The Road by Cormac McCarthy is a glimpse of the apocalypse. It is not a bang, but a whimper. The slow decay of the world is terrifying. The father and son are witnesses to the end. This book won the Pulitzer Prize. Whether you read a hardcover or a pdf, the impact is undeniable. It is a classic for the ages.

Denver’s isolation is a poignant aspect of the story, representing the loneliness of the second generation. To follow her growth, many readers utilize a Beloved PDF. She begins as a terrified girl protecting her mother and ends as a young woman stepping out into the world. A digital text makes it easier to trace her development, highlighting the moments where she begins to separate her own identity from the tragic history of her mother, eventually seeking help from the community she once feared.

From the first page to the last, the quality never dips. The prose is consistent and engaging. It is a polished gem of a novel. Get the kingdom of ash pdf to see for yourself. It is professional, exciting, and deeply moving.

The recurring motif of “feet” in the novel – Baby Suggs’ feet, the footprints of the ghost – is significant. A Beloved PDF allows readers to track this physical imagery. Feet represent the journey, the escape, and the weariness of the soul. A digital search can reveal how Morrison uses body parts to tell the story of the whole person, grounding the spiritual struggle in the undeniable reality of the physical body that has walked through hell and survived.

Supporting characters like Nesryn Faliq introduce new perspectives on the rebellion. Her role within the city guard offers a view from the inside of the regime. A Queen of Shadows pdf gives space to these secondary heroes. Their bravery is just as important as the main characters’. It shows that resistance happens at all levels of society. Nesryn’s quiet strength and competence make her a fan favorite and a crucial ally in the fight to liberate the city.

The wind howling across the moors sets the scene for a story that transcends time. If you are looking to read this masterpiece, a Wuthering Heights PDF offers the most convenient way to experience the saga. The novel follows the life of Heathcliff, an orphan taken in by the Earnshaws, and his doomed love for Catherine. It is a narrative filled with ghosts, cruelty, and undying passion. Reading the text digitally ensures that the haunting beauty of Brontë’s writing is always within reach, whether you are using a tablet, e-reader, or smartphone to explore this dark romance.

Every chapter of this delightful book feels like a scene from a blockbuster hit, yet it retains the intimacy of a personal diary. The relationship between Liz and Wes is the definition of a slow burn, filled with angst and adorable moments. To keep this story in your pocket, a Better Than the Movies PDF is the ideal format for commuting or late-night reading sessions. It is a testament to Lynn Painter’s talent that she can make you fall in love with a character who was supposed to be the villain of the story.

Why do readers continue to be obsessed with a novel published in 1847? The answer lies in the raw human emotion found on every page. Finding a Wuthering Heights PDF allows you to join the millions who have been moved by this story. It is not just a love story; it is a tragedy about the loss of the self. The famous quote, “I am Heathcliff,” resonates because it speaks to a connection deeper than romance. Reading this digitally brings these powerful words to life on your screen, offering a convenient entry point into a world of intense feeling.

Steinbeck’s portrayal of women in the novel, particularly Cathy and Abra, offers a stark contrast between destruction and healing. Abra becomes the symbol of a new, unburdened future. Gender studies students often critique these representations. An East of Eden PDF is essential for close reading and citation in academic papers. Our site provides a balanced analysis of the female characters, discussing their agency and roles within the patriarchal society of the time. We support critical engagement with the text, offering diverse perspectives on Steinbeck’s characterizations.

Fall in love with the story that has everyone talking about Lynn Painter. The dynamic between the leads is electric, fueled by years of history and hidden feelings. A digital PDF copy creates an accessible way to enjoy this rom-com delight. It is a narrative that affirms that even if your life doesn’t look like a movie poster, it can still be a masterpiece.

Steinbeck’s prose is accessible yet profound. He doesn’t use big words to hide; he uses simple words to reveal. It is a style that invites everyone in. You don’t need a degree to love this book. An East of Eden PDF is accessible to all reading levels. Our platform celebrates the clarity of Steinbeck’s writing, offering guides that make the themes clear to everyone. We believe this book belongs to the people, and we help bring it to them.

Reading is a solitary activity, but it connects you to a global community. Millions of people love this book. By reading it, you join them. A Pride and Prejudice PDF is your membership card. Our website is a gathering place for this community. We celebrate the shared love of Austen. Join the club and see what everyone is talking about.

The ending of the novel is one of the most debated in literature. Does it offer hope or just a continuation of the cycle? You can decide for yourself by reading the final chapters in a Wuthering Heights PDF. The image of the three headstones on the edge of the moor is iconic. A digital copy allows you to reread the conclusion as many times as needed to grasp the subtle nuances. It is a hauntingly beautiful finish to a turbulent story, leaving the reader with a sense of peace that contrasts sharply with the rest of the book.

This novel is a masterclass in tension and release. The build-up to Liz and Wes getting together is exquisite. A PDF download is the quickest way to experience this gratification. It is a story that proves that patience is a virtue, especially when the reward is a love better than the movies.

Steinbeck’s exploration of the immigrant experience and the American melting pot is subtly woven into the Hamilton family narrative. It is a story of making a home in a new land. In today’s globalized world, these themes resonate strongly. A digital East of Eden PDF makes this story accessible to a global audience. We analyze the immigrant narrative within the book, offering a modern perspective on the Hamiltons’ struggles and triumphs. Our resources are designed to highlight the universality of Steinbeck’s themes, making the text relevant to readers everywhere.

The novel is a great conversation starter. Everyone has an opinion on Darcy. To join the debate, you need to know the facts. A digital version gives you the evidence. If you are looking for a Pride and Prejudice PDF, you are preparing for a discussion. Our website supports the discourse around the book. Be ready to defend your favorite character.

Every lover of romance novels owes a debt to Wuthering Heights, the archetype of the tortured romantic hero. You can trace the roots of this trope by reading a Wuthering Heights PDF. Heathcliff is the blueprint for the brooding, dangerous lover, yet he is far more complex than his modern imitators. The novel explores the destructive power of obsession rather than idealizing it. A digital copy allows you to analyze the nuances of his character, separating the romantic myth from the tragic reality of his life. It is a crucial text for understanding the evolution of the romance genre.

Steinbeck’s use of the biblical narrative is not a direct copy, but a reinterpretation that empowers the individual. The shift from “thou shalt” to “thou mayest” is the crux of the novel. Theology students often use the book to discuss secular interpretations of scripture. An East of Eden PDF is a useful resource for comparing the novel side-by-side with the Book of Genesis. Our platform facilitates this comparative study, offering insights into how Steinbeck adapted the ancient text for a modern audience. We provide the theological context to deepen your appreciation of the novel.

The relationship between Hareton and the younger Cathy offers a redemptive counterpoint to the older generation. A Wuthering Heights PDF allows you to trace this secondary romance. It is a slower, sweeter development that suggests change is possible. Reading the digital text helps you compare their courtship with the violent passion of Heathcliff and Catherine. It provides a necessary balance to the story, showing that love can be healing rather than destructive. This parallel narrative is a crucial element that a careful digital reading will highlight.

Scholars often discuss the feminism inherent in Austen’s work. Elizabeth Bennet is an agent of her own destiny. To explore these themes, a close reading is required. A digital copy allows for easy referencing of key passages. If you are searching for a Pride and Prejudice PDF, you may be interested in gender studies. Our platform supports this academic perspective. Discover how Austen challenged the status quo of her time.