by William | Nov 3, 2021 | Small Footprint

Dear Readers,

I would like to introduce you to a phenomenal business that shares the same mountain range as the Land of the Laurels, just a bit further South: Bark House. Based in Spruce Pine, North Carolina, Bark House began in 1990 by a wife and husband team~ Chris and Marty McCurry. Committed to providing sustainably sourced bark shingles for interior and exterior applications on homes and buildings, they have earned over a dozen different awards and recognitions, including but not limited to: Cradle to Cradle Platinum certification, they are a Certified B Corporation, they have had a Declare Label Red List Free for their Poplar bark shingles, and they were awarded by their local non-profit, Root Cause, as a Support of Local Wood Products Award.

The recognition they have received globally and locally is noteworthy. However, it is just that. Noteworthy. On paper it is impressive, and it deserves to be shared…literally, worthy of noting. But the power behind this business lies not in their stamps or their certifications…or even in that Google and Amazon use their bark frequently in their establishments. The power Bark House holds, lies in the good they have done, are doing, and will continue to do for the Appalachian Mountain Range and the small communities that call it home.

Getting the Bark

Their process of obtaining the bark is based entirely off of regenerative practices~ for the environment, and their community. They began their business with the training of 50 local loggers on how to peel bark off felled trees. The loggers could then sell the trees they took down as profit, as well as the bark from those trees.

by William | Jun 23, 2021 | Passive House

Dear Readers,

As many of you are already well aware, William and I are hopeful people. Admittedly, William more than I. I can be a bit of a negative nancy at times.

All optimism and pessimism aside, I like to think we can be quite grounded in our hope. One of the handful of products we are hoping on, and crossing our fingers that it may indeed be on the market by the time we actually build our house, is wood fiber insulation by Go Lab.

Expected to be on the market in 2022, Go Lab is bringing wood fiber insulation to the United States~ Maine, to be specific! They will offer wood fiber batt insulation, dense pack and loose fill wood fiber insulation, and continuous wood fiber board insulation. Which is great! Howeverrrrr…we really only want the continuous board wood fiber insulation.

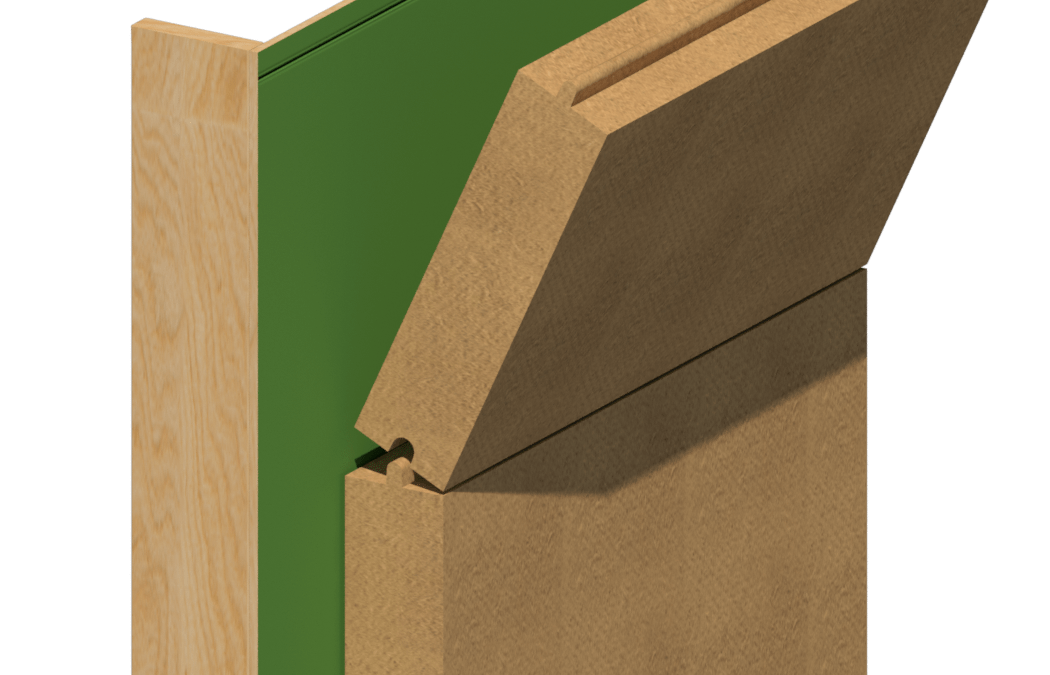

When looking at William’s beautiful wall section…

by William | Dec 16, 2020 | Net Zero, Small Footprint

Dear Readers,

First came place, then came water. Now, comes energy…dun, dun, dun! The Energy Petal is the third of the seven petals for the Living Building Challenge.

Ha! I was going to say that we have high hopes for this one…but we have high hopes for the Water Petal and the Petal of Place, too. There are just way too many high hopes floating around this joint! But. If you are willing to stick with us (whether you are amused or annoyed by our ideas…), then William and I would be most honored to share our highness of hope with you!

To refresh your memory, here is a chart with all seven petals and their imperatives. In this blog, we are going to be focusing on Energy!

by William | May 6, 2020 | Passive House, Small Footprint

Dear Readers,

William and I had the opportunity to listen in on a webinar provided by the Passive House Institute of the United States (PHIUS) on limiting embodied carbon in buildings: “Spaghetti Carbon-Era: Disentangling Operational and Embodied Carbon.” Admittedly, I just got the pun of the title…which is all the more humorous if you were to have seen their intro presenting page being that of pasta in a white sauce with bacon.

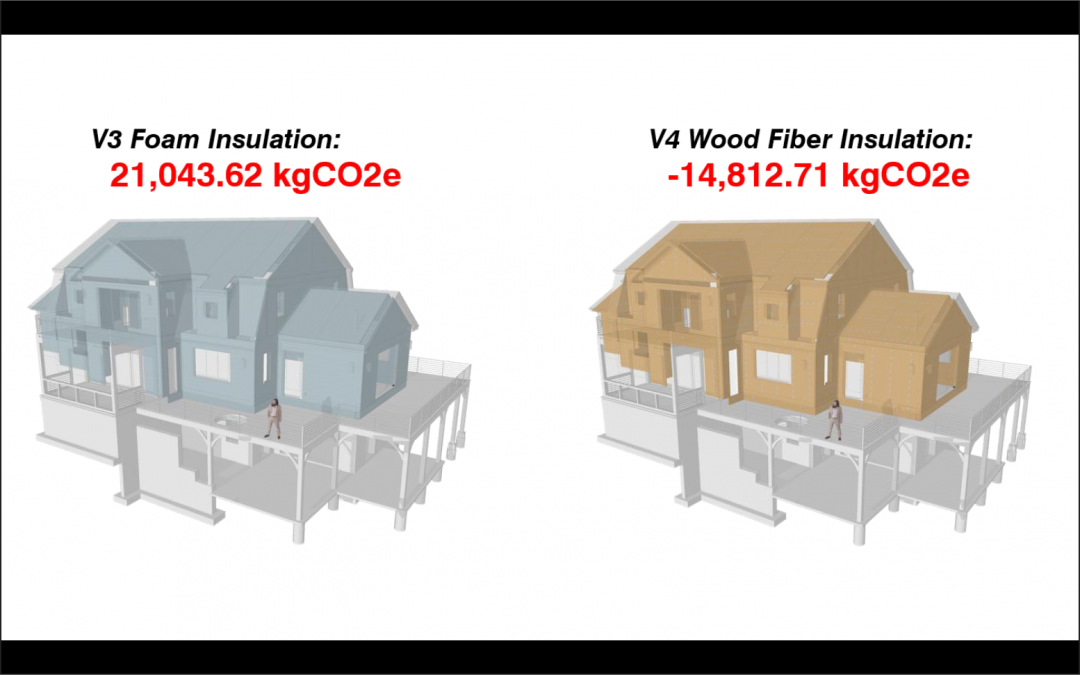

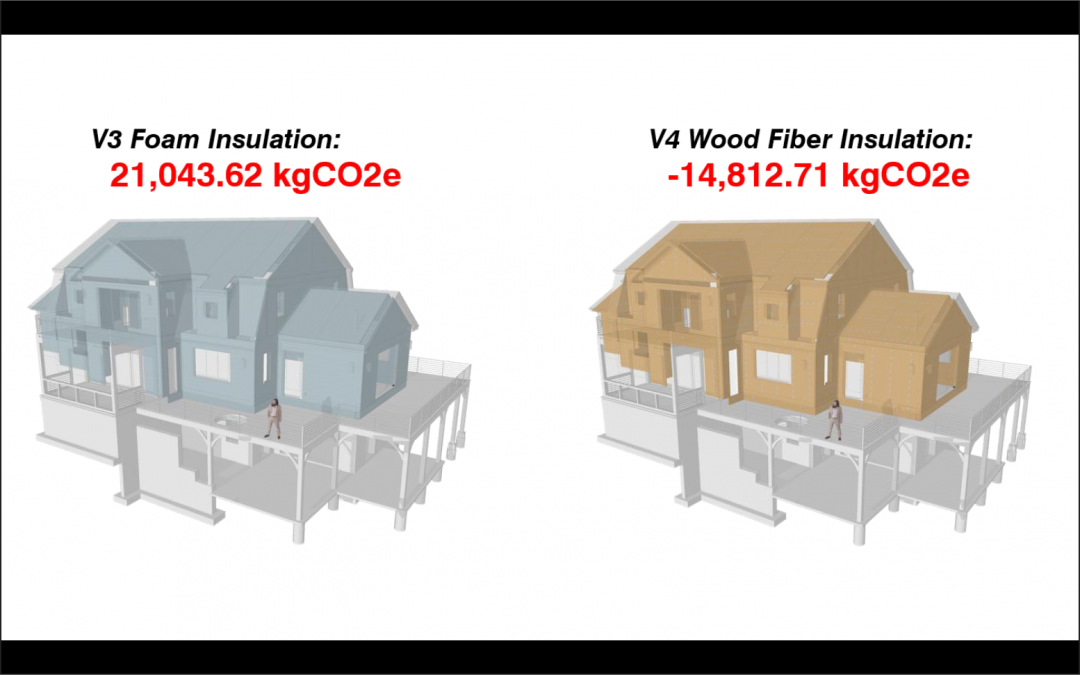

This seminar was very helpful in reiterating the importance of taking a holistically sustainable approach in home building and living. Not only should the home be environmentally friendly and energy efficient during its usage, but also in its construction and sourcing of materials. The ‘environmentally friendliness’ here is measured by the amount of carbon a home is responsible for emitting. PHIUS standards make a home accountable for its carbon footprint in its operation alone: as in, how much energy the home needs to function once it is already built. This they call “operational carbon” or, “OCO2e.” In the webinar, they expressed that the home has an even larger carbon footprint when its “embodied carbon” or, “ECO2e” is taken into account. Embodied carbon is the amount of carbon that is emitted in the overall construction of the home: from the harvesting, manufacturing, and transportation processes of all of the home’s required building materials. That pink fluffy fiberglass insulation and wooden studs and concrete foundation and drywall has to be made out of something and transported from somewhere…all of the materials have their own carbon footprints which then contribute to the home’s overall embodied carbon.

Two of the presenters, Ilka Cassidy and Steve Hessler, founded a business called “Holzraum System, LLC.” Within their business, they did their own study of how much of a home’s carbon footprint is operational and how much of it is embodied. They used five different homes as case studies.

Home One: built to meet 2009 building code

Home Two: built to meet 2009 building code with high performance systems

Home Three: built to meet Passive House standards, but with a high usage of foam

Home Four: built to meet Passive House standards, but with a low usage of foam

Home Five: built to meet Passive House standards, but with no foam.