by William | Sep 9, 2020 | Healthy Living, Net Zero, Passive House, Prefabrication, Small Footprint

I swear, Onion Flats does it all. They do architecture. They do development. They do construction. They even do green roofs totally decked out with solar panels. They do all of this with sustainability in mind. They are utterly revamping Philadelphia, Pennsylvania to be a hub for Passive House and Net Zero readiness. Their primary goal is to reduce the operational carbon footprint of their buildings, while also admitting that embodied carbon in buildings will need to be considered if we really want to reach a sense of stable sustainability. And not only do they have a heart for green building and design…but they also have a heart to share it with our low-income, swept-under-the-carpet communities. They are physically building a world where sustainability should not just be “for the rich.”

Their completed project, Belfield, is the primary example I, personally, really want to look at. They have other incredible projects in Philadelphia which I strongly encourage you to take the independent, personal initiative to check out! But since I’m the one writing this blog, I am writing about Belfield.

The Belfield Townhomes development was Onion Flats’ first in just about everything. It was their first build from the ground-up, their first certified Passive House (PHI), and it was their first experimental prefab project. Firsts are scary. And they are even scarier when you have a time crunch. In order to qualify for federal funding, they had to design and build the modular Passive House townhomes in five months. Five months.

But the initiative was there. The townhomes were intended for “formerly homeless and low-income families” supported by the Philly non-profit, Raise of Hope. Environmentally friendly, affordable, healthy homes for the homeless…Onion Flats was all in.

by William | Aug 12, 2020 | Healthy Living, Net Zero, Passive House, Prefabrication, Small Footprint

Dear Readers,

Welcome to our fifth Home Building Curiosity….Go Home! A division of Go Logic, Go Home is a design/build prefab Passive House enthusiast leading the way in energy efficient design and the continuation of learning.

Maine based, Go Homes are inspired by their local region’s natural landscape, as well as by its history, people, and culture.

All of their Go Homes meet Passive House (PHIUS) standards, and are prefabricated through a honed panelization process.

Passive House

An advocate for building homes that have the earth and future generations in mind, Go Home makes all their homes go passive. Achieving Passive House certification means that homes will use less energy, thereby paving the road to being net zero, or even net positive. A house requiring less energy to function, means less energy is needed in the first place.

Their homes’ air-tightness “meets or exceeds” Passive House (PHIUS) standards at .6 air changes per hour at 50 pascals (.6 ACH @ 50 Pa). And their homes are all crazy well insulated, as you shall read in the ‘prefabricated’ section.

They offer heat-recovery and energy-recovery ventilation systems with all of their homes. Three pane, high quality, windows are also utilized and placed accordingly to maximize heat gains from solar energy.

Go Home’s commitment to making not only their homes, but the world, Passive, can be admirably summed up in their last paragraph on their “Passive House” page:

by William | Jul 22, 2020 | Net Zero, Passive House, Prefabrication

Dear Readers,

Ready for the fourth edition to our Home Building Curiosity collection? Here are some dramatic hints to what you are about to absorb…

…[intense, theatrical music playing]…The home’s structure is cross laminated timber, it’s reinforced with galvanized steel frames to allow it to fold from a box to a customizable A-frame home in less than seven hours, it has the possibility to meet Passive House standards with its high density rockwool insulation and waterproofing polyurethane foam, the models range from 365.97 to 925.7 square feet, it’s a masterpiece by architect Renato Vidal…it’s innovative…it’s modular…it’s Italian…it’s MADi!

[Right about here, the crowd would go wild]

Prefabricated

MADi’s goal is to make homes more affordable to us Average Joe’s, and they achieve this initiative through a perfected prefabrication system. They use cross laminated timber (CLT) in their construction…which greatly speeds up the manufacturing process while maintaining a high quality build. Panels of CLT can be routed in the factory to meet design requirements, and then put together like building blocks to make a home. They are the structure of the home….and a strong, fire and earthquake resistant one at that.

How the MADi homes are assembled on-site makes William’s roof origami look incredibly feasible….

by William | Jul 1, 2020 | Healthy Living, Net Zero, Passive House, Prefabrication, Small Footprint, Uncategorized

Dear Readers,

Welcome to our third Home Building Curiosity, Ecocor! As with the first two Home Building Curiosities, Ecocor is not only a curiosity, but an inspiration in the field of sustainable building. Ecocor is exceptional in how it actually meets all five of William and I’s foundational principles in our mission. Based in Searsmont, Maine, Ecocor designs and manufactures prefabricated, Passive House (PHI) certified, net zero ready, small footprint, healthy living building components and homes.

Prefabricated

Ecocor is very proud of their wall panels, and they rightly should be! Their walls are prefabricated at their Searsmont location, allowing for a climate-controlled build of each panel. Every wall panel meets Passive House standards, and has a specific assembly structure that is even being patented.

The manufacturing of individual wall panels allows Ecocor, the architect, and the buyer to get creative, while still achieving a quickly and quality built home. They promote the motto of “If it can be drawn, we can build it.” Think of their walls as super insulated, airtight, lego blocks, that allow you to build your own unique passive home.

While their wall panels are prefabricated and allow custom builds, Ecocor does have a sector devoted to prefabricated, Passive House certified, modular homes. This branch is called Solsken, which means “sunshine” in Swedish. All of the homes in their Solsken Ecocor collection are named after flowers, which William and I love (because we were actually thinking of naming our potential pipe-dream homes after trees)!

by William | May 6, 2020 | Passive House, Small Footprint

Dear Readers,

William and I had the opportunity to listen in on a webinar provided by the Passive House Institute of the United States (PHIUS) on limiting embodied carbon in buildings: “Spaghetti Carbon-Era: Disentangling Operational and Embodied Carbon.” Admittedly, I just got the pun of the title…which is all the more humorous if you were to have seen their intro presenting page being that of pasta in a white sauce with bacon.

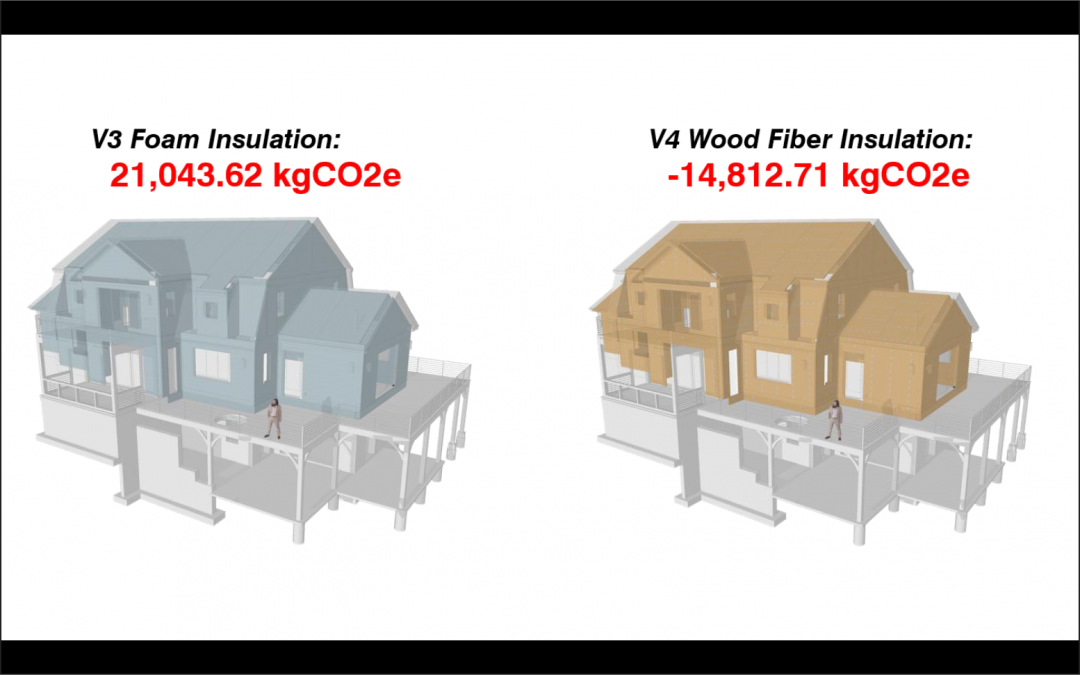

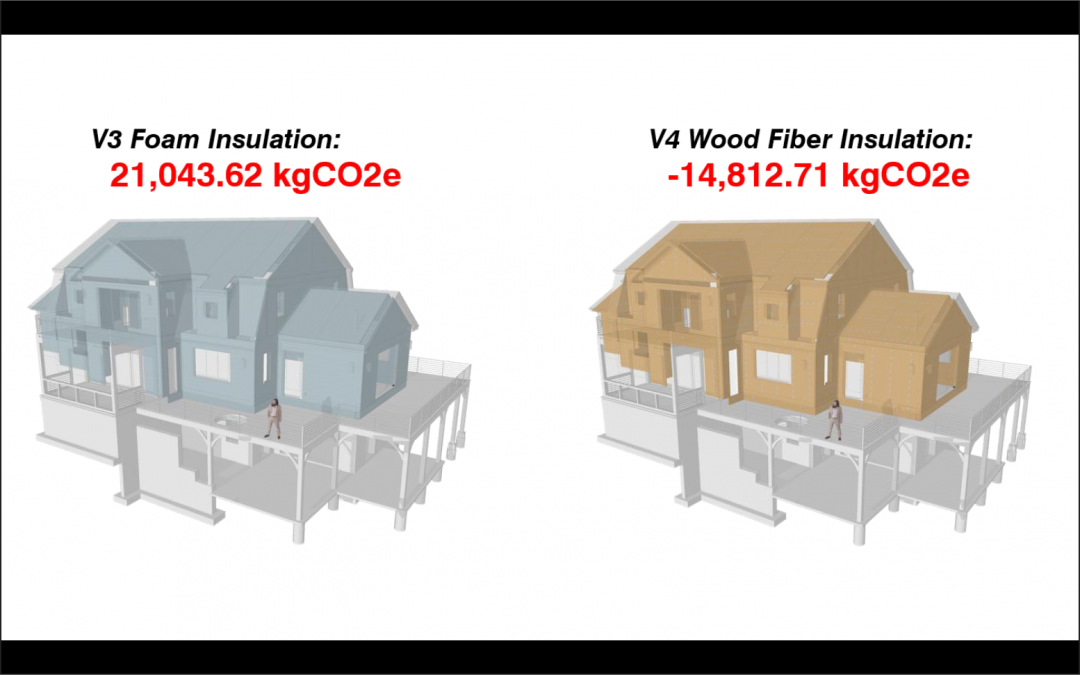

This seminar was very helpful in reiterating the importance of taking a holistically sustainable approach in home building and living. Not only should the home be environmentally friendly and energy efficient during its usage, but also in its construction and sourcing of materials. The ‘environmentally friendliness’ here is measured by the amount of carbon a home is responsible for emitting. PHIUS standards make a home accountable for its carbon footprint in its operation alone: as in, how much energy the home needs to function once it is already built. This they call “operational carbon” or, “OCO2e.” In the webinar, they expressed that the home has an even larger carbon footprint when its “embodied carbon” or, “ECO2e” is taken into account. Embodied carbon is the amount of carbon that is emitted in the overall construction of the home: from the harvesting, manufacturing, and transportation processes of all of the home’s required building materials. That pink fluffy fiberglass insulation and wooden studs and concrete foundation and drywall has to be made out of something and transported from somewhere…all of the materials have their own carbon footprints which then contribute to the home’s overall embodied carbon.

Two of the presenters, Ilka Cassidy and Steve Hessler, founded a business called “Holzraum System, LLC.” Within their business, they did their own study of how much of a home’s carbon footprint is operational and how much of it is embodied. They used five different homes as case studies.

Home One: built to meet 2009 building code

Home Two: built to meet 2009 building code with high performance systems

Home Three: built to meet Passive House standards, but with a high usage of foam

Home Four: built to meet Passive House standards, but with a low usage of foam

Home Five: built to meet Passive House standards, but with no foam.

by William | Apr 1, 2020 | Passive House

What is a British Thermal Unit (BTU)? Dear Readers, Through William and I’s endeavors to understand Passive House standards, and my personal endeavors to gain a basic understanding of architecture, I have come across quite a few significant moments. One of which being...